Process Optimization in Ethanol Production: Best Practices

- hr30522

- Aug 21, 2024

- 8 min read

Updated: Nov 22, 2024

In a world increasingly focused on sustainable energy solutions, ethanol production remains a key player in the renewable energy sector. However, as environmental regulations tighten and competition intensifies, the need for optimizing ethanol production processes has never been more critical. To thrive in this evolving industry, producers must adopt best practices and leverage cutting-edge technologies to maximize yield, reduce costs, and enhance sustainability. This comprehensive guide explores the intricate details of optimizing ethanol production, offering practical strategies and real-world examples to help you achieve excellence in every facet of the process.

Understanding the Ethanol Production Process

To effectively optimize ethanol production, it's essential to grasp the complexities of the process. Ethanol production involves several key stages: feedstock preparation, saccharification, fermentation, distillation, dehydration, and byproduct management.

Feedstock Preparation:

Feedstock preparation is the foundational step in ethanol production, setting the stage for the entire process. It involves selecting and preparing the feedstock for conversion into ethanol.

Feedstock Selection: The choice of feedstock is crucial as it affects every subsequent stage of production. Corn is widely used due to its high starch content, but other feedstocks like sugarcane, wheat, barley, and emerging options like switchgrass and algae offer different benefits. Sugarcane, for instance, contains high levels of fermentable sugars, which can streamline the saccharification process. Switchgrass, a perennial grass, is favored for its lower water and fertilizer requirements, contributing to its sustainability. Algae, grown in non-arable lands, provides a high yield of energy and has minimal environmental impact. When selecting feedstock, consider factors such as availability, cost, yield potential, and environmental impact.

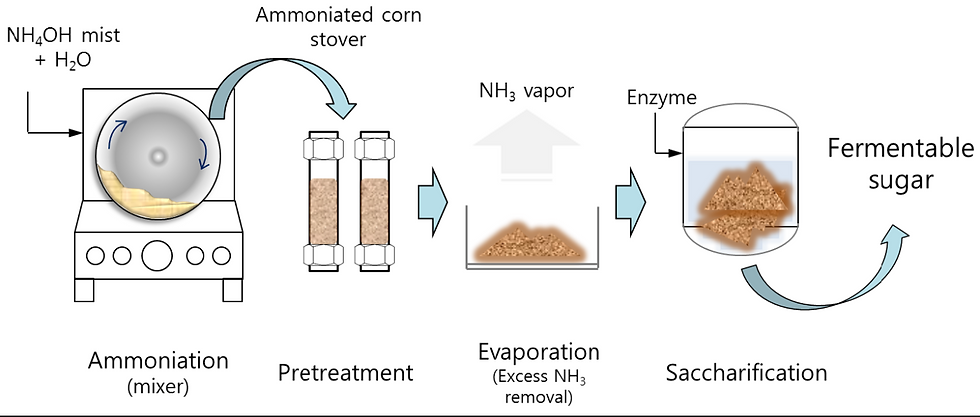

Feedstock Preparation: Proper feedstock preparation involves several critical steps:

Cleaning: Removes impurities and contaminants that could affect the efficiency of subsequent processes. This step ensures that only high-quality feedstock is processed.

Pre-treatment: Enhances the feedstock’s suitability for saccharification. Methods such as steam explosion and acid hydrolysis are employed:

Steam Explosion: Exposes the feedstock to high-pressure steam, causing rapid expansion and rupturing of cell walls. This process improves the accessibility of carbohydrates for enzymatic action.

Acid Hydrolysis: Uses acid to break down complex carbohydrates into simpler sugars. This method is particularly useful for lignocellulosic feedstocks, which have complex structures.

Saccharification:

Saccharification is the process of converting complex carbohydrates into fermentable sugars. This step is critical for achieving high ethanol yields.

Enzyme Optimization: The choice of enzymes and their concentration can significantly impact saccharification efficiency. Key enzymes include:

Glucoamylase: Converts maltose into glucose.

Cellulase and Hemicellulase: Break down cellulose and hemicellulose in lignocellulosic feedstocks. Enzyme formulations should be tailored to the specific feedstock being used. For instance, a feedstock with high starch content may require a different enzyme blend compared to one with high fiber content. Enzyme activity can be monitored through assays measuring glucose release, helping to adjust dosages and formulations for optimal performance.

Process Conditions: Enzymes operate best within specific temperature and pH ranges. Maintaining these conditions is essential for optimal enzyme activity.

Temperature: Most enzymes work best at temperatures between 50-70°C. Deviations can reduce enzyme activity and efficiency.

pH: The optimal pH range varies by enzyme type but generally falls between 4.5 and 6.5. Monitoring and adjusting pH levels ensure enzymes remain active and effective. Real-time monitoring systems can help maintain ideal conditions by providing continuous data on temperature and pH, allowing for immediate adjustments.

Fermentation:

Fermentation is where yeast converts sugars into ethanol and carbon dioxide. Optimizing this stage is crucial for maximizing ethanol yields.

Yeast Strain Selection: The yeast strain used in fermentation can significantly influence efficiency and yield. Key considerations include:

Ethanol Tolerance: Yeast strains with higher ethanol tolerance can withstand higher concentrations of ethanol, reducing the risk of fermentation stalls and ensuring complete conversion of sugars.

Temperature and Sugar Tolerance: Different strains have varying tolerances to temperature and sugar levels. Choosing a strain that matches the feedstock and fermentation conditions can enhance performance.

Genetically Engineered Strains: Some strains are genetically modified to improve performance, such as increased sugar uptake or resistance to inhibitors.

Fermentation Conditions: Maintaining optimal fermentation conditions is essential for yeast health and activity. Key parameters include:

Temperature: Yeast generally performs best at temperatures between 28-32°C. Deviations can slow fermentation or reduce ethanol yield.

pH: The optimal pH for most yeast strains is between 4.5 and 5.5. Regular pH monitoring and adjustment are necessary to maintain yeast activity.

Nutrient Availability: Adequate nutrients such as nitrogen, vitamins, and minerals are crucial for yeast growth and fermentation. Ensuring proper nutrient levels can enhance fermentation efficiency.

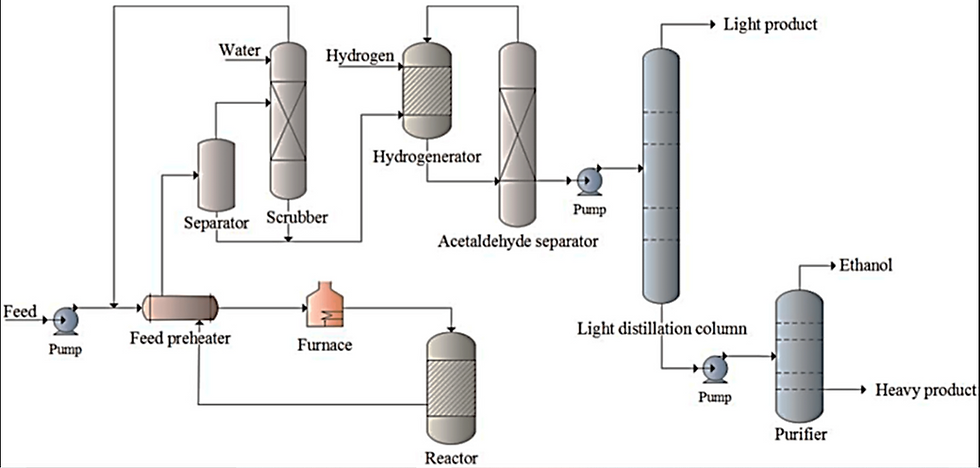

Distillation:

Distillation separates ethanol from the fermentation mixture based on boiling points. Optimizing this stage improves ethanol purity and reduces energy consumption.

Distillation Parameters: Key parameters affecting distillation efficiency include:

Reflux Ratio: The ratio of liquid returned to the distillation column versus the liquid taken off. A higher reflux ratio increases ethanol purity by enhancing the separation process.

Column Pressure: Pressure within the distillation column can impact ethanol boiling points and separation efficiency. Adjusting column pressure can optimize the distillation process.

Temperature Control: Precise temperature control is essential for effective separation. Implementing advanced temperature control systems can enhance distillation efficiency.

Energy Efficiency: Distillation is energy-intensive, and adopting energy-saving technologies can reduce costs and environmental impact. Strategies include:

Multi-Effect Distillation: Uses heat from one distillation stage to drive subsequent stages, improving overall energy efficiency.

Heat Integration: Recovers and reuses heat from various stages of production, reducing additional energy input and lowering operational costs.

Advanced Heat Exchangers: Utilize efficient heat exchangers to minimize energy loss and improve heat recovery.

Dehydration:

Dehydration removes residual water from ethanol to produce anhydrous ethanol, suitable for fuel applications.

Dehydration Technologies: Several technologies are used for dehydration, each with its advantages:

Molecular Sieves: Highly effective at removing water from ethanol, achieving very low water content. Molecular sieves work by adsorbing water molecules while allowing ethanol to pass through.

Azeotropic Distillation: Adds substances to the ethanol-water mixture to form azeotropes, which are then removed. This method can be effective for achieving high ethanol purity.

Pressure Swing Adsorption: Uses adsorption materials to separate water from ethanol. This method can be advantageous for continuous operations and high-efficiency separation.

Performance Monitoring: Regular monitoring of dehydration units is crucial for maintaining efficiency and product quality. Key parameters include:

Water Content: Monitoring the water content in the ethanol ensures it meets required specifications.

Sieve Performance: Evaluating the performance of molecular sieves and other dehydration materials to ensure optimal efficiency. Scheduled maintenance and performance testing can prevent issues and ensure the dehydration process remains effective.

Byproduct Management:

Managing byproducts effectively can enhance overall process efficiency and sustainability. Byproducts such as distiller’s grains are generated during ethanol production and can be repurposed or minimized.

Byproduct Utilization: Distillers grains, a byproduct of ethanol production, can be used in various ways:

Animal Feed: Processed into high-protein animal feed, providing a cost-effective feed ingredient for livestock.

Fertilizers: Converted into organic fertilizers that improve soil health and reduce the need for synthetic fertilizers.

Bio-based Products: Used in the production of bio-based materials or biogas, contributing to a circular economy.

Waste Reduction: Implementing waste reduction strategies can minimize environmental impact:

Closed-Loop Systems: Recycle and reuse water within the facility, reducing overall water consumption and wastewater discharge.

Alternative Water Sources: Explore options such as rainwater harvesting to supplement water needs and reduce dependency on external sources.

Material Recycling: Implement recycling programs for materials used in production processes to reduce waste and promote sustainability.

Embracing Advanced Technologies:

Advanced technologies play a vital role in optimizing ethanol production by improving efficiency, reducing costs, and supporting sustainability.

Automation and Control Systems

Automation and advanced control systems enhance precision, consistency, and overall process efficiency.

Process Control Systems: Automated control systems provide real-time monitoring and adjustment of process conditions. Key benefits include:

Precision Control: Ensures that temperature, pH, and other parameters remain within optimal ranges, reducing variability and improving product quality.

Reduced Manual Intervention: Minimizes the need for manual adjustments, reducing the risk of human error and improving operational efficiency.

Real-Time Data: Provides continuous data on process conditions, enabling timely interventions and adjustments to maintain optimal performance.

Data Analytics: Leveraging data analytics tools can uncover insights and drive process improvements:

Trend Analysis: Identifies trends and patterns in production data, revealing areas for optimization and potential issues.

Predictive Analytics: Uses historical data and machine learning algorithms to forecast potential issues and suggest preventative measures.

Performance Benchmarks: Compares performance against industry benchmarks to identify areas for improvement and implement best practices.

Improving Energy Efficiency:

Enhancing energy efficiency is crucial for reducing production costs and minimizing environmental impact.

Energy-Efficient Technologies: Investing in energy-efficient equipment and systems can lead to significant savings:

Combined Heat and Power (CHP) Systems: Generate electricity and useful heat from a single energy source, improving overall energy utilization and reducing costs.

High-Efficiency Boilers: Utilize advanced technology to improve combustion efficiency and reduce fuel consumption.

Heat Recovery Systems: Capture and reuse waste heat from various stages of production, reducing the need for additional energy input.

Monitoring Energy Usage: Regularly track and analyze energy usage to identify opportunities for improvement:

Energy Management Systems: Implement systems to monitor and optimize energy use throughout the facility, identifying areas for efficiency gains.

Energy Audits: Conduct regular energy audits to assess energy consumption and identify potential savings opportunities.

Operational Adjustments: Make adjustments to processes and equipment based on energy data to reduce consumption and costs.

Implementing Sustainability Practices

Sustainability is a key focus in modern ethanol production, driven by regulatory requirements, consumer preferences, and environmental goals.

Renewable Energy Sources: Incorporating renewable energy sources can reduce reliance on fossil fuels and lower greenhouse gas emissions:

Solar Power: Install solar panels to generate electricity and reduce dependence on conventional energy sources.

Wind Power: Invest in wind turbines to harness wind energy and support facility operations.

Biomass Energy: Utilize biomass from feedstocks or byproducts to generate energy, further supporting sustainability goals.

Reducing Water Usage: Implement strategies to minimize water consumption and promote sustainable water management:

Closed-Loop Water Systems: Recycle and reuse water within the facility to reduce overall consumption and wastewater discharge.

Water-Saving Technologies: Use technologies such as high-efficiency pumps and water-saving fixtures to reduce water use.

Alternative Water Sources: Explore options such as rainwater harvesting or greywater recycling to supplement water needs and reduce external dependence.

Real-World Success Stories:

Examining real-world examples of successful process optimization provides valuable insights and practical lessons for achieving excellence in ethanol production.

Boosting Fermentation Efficiency:

A mid-sized ethanol plant faced challenges with fermentation inefficiencies, resulting in lower yields and higher production costs. The plant implemented the following changes:

New Yeast Strain: Introduced a yeast strain specifically designed for high sugar concentrations, improving fermentation efficiency.

Optimized Conditions: Adjusted temperature, pH, and nutrient levels to better suit the new yeast strain. The results were impressive—a 15% increase in ethanol yield and reduced production costs. This case highlights the importance of selecting the right yeast strain and maintaining optimal fermentation conditions to enhance performance.

Reducing Energy Costs:

A large-scale ethanol producer faced high energy costs and sought to improve sustainability. The company took the following steps:

Advanced Distillation Equipment: Invested in new distillation equipment with energy-saving technologies.

Combined Heat and Power (CHP) System: Implemented a CHP system to generate electricity and useful heat from a single energy source. These investments led to a 20% reduction in energy costs and a significant decrease in greenhouse gas emissions. The case demonstrates the financial and environmental benefits of investing in energy-efficient technologies.

Enhancing Byproduct Utilization:

An ethanol facility aimed to maximize the value of distiller’s grains, a byproduct of ethanol production. The facility:

Developed a Byproduct Management Strategy: Created a process to convert byproducts into high-protein animal feed.

Established Partnerships: Partnered with local livestock producers to utilize the feed and generate additional revenue. This strategy resulted in a 25% increase in overall profitability and improved the facility’s environmental footprint. The case illustrates the benefits of effective byproduct utilization and waste reduction.

Conclusion:

Optimizing the ethanol production process is a multifaceted endeavor that requires a deep understanding of each stage, a commitment to continuous improvement, and a willingness to embrace new technologies and practices. By focusing on best practices, implementing advanced technologies, and committing to sustainability, you can achieve significant improvements in efficiency, yield, and environmental performance.

The ethanol industry is continually evolving, with new advancements and best practices emerging regularly. Staying informed about the latest developments, regularly reviewing and refining your processes, and adopting innovative solutions will help you maintain a competitive edge and advance the renewable energy revolution.

Ultimately, optimizing ethanol production is not just about achieving higher yields and lower costs—it’s about making a positive impact on the environment and contributing to a sustainable energy landscape. By embracing these practices and committing to ongoing improvement, you’ll be well on your way to achieving excellence in ethanol production and supporting a greener, more sustainable world.

#EthanolProduction #ProcessOptimization #BestPractices #EfficientManufacturing #EthanolTech #ProductionEfficiency #ManufacturingExcellence #OptimizedProcesses #EthanolIndustry #SustainableProduction #TechInEthanol #OperationalExcellence #ProcessImprovement #EthanolInnovation #ProductionBestPractices #EnergyEfficiency #ManufacturingOptimization #ProcessEngineering #EthanolSolutions #AdvancedManufacturing

Comments